Our Products

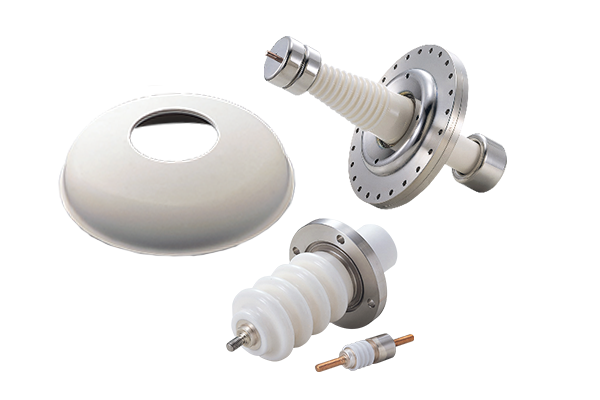

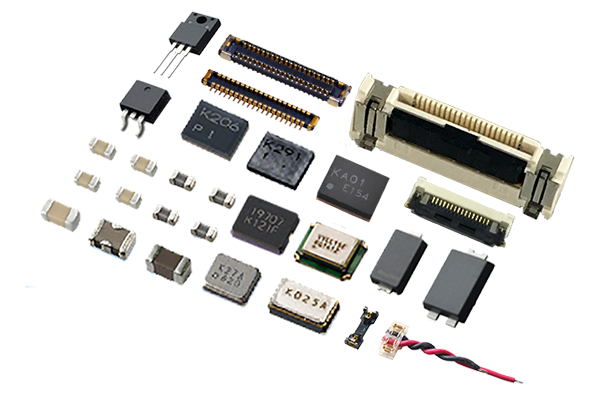

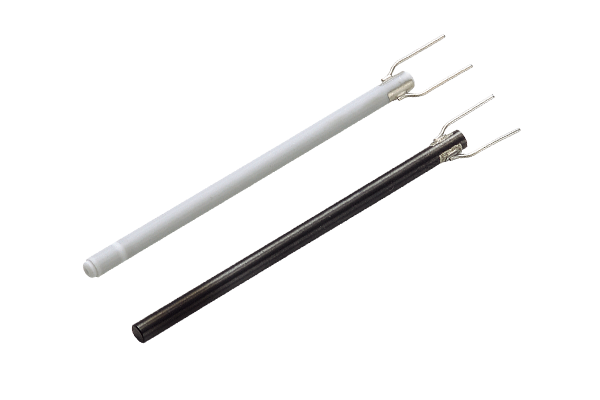

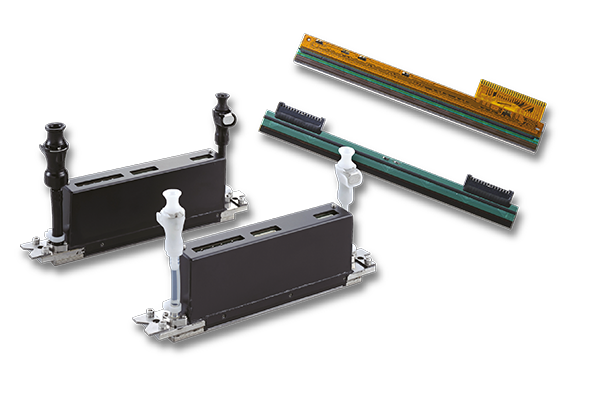

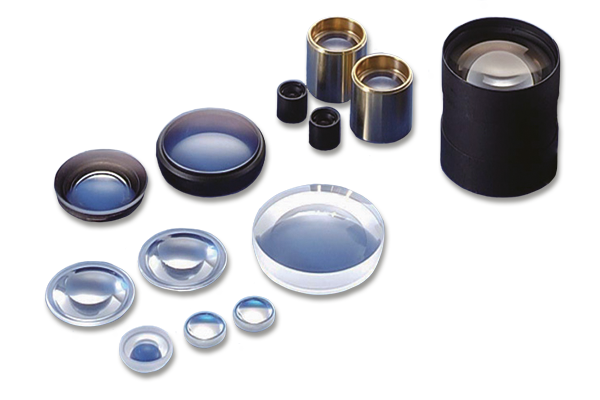

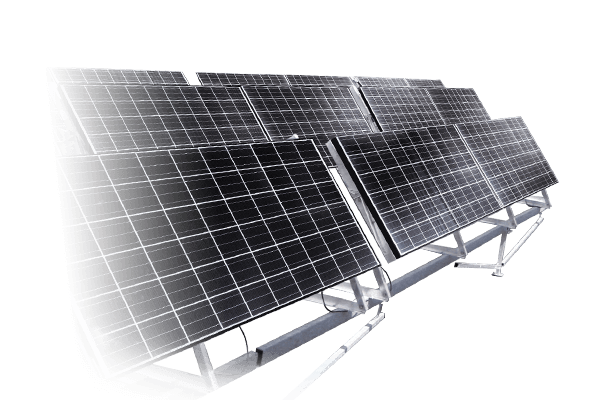

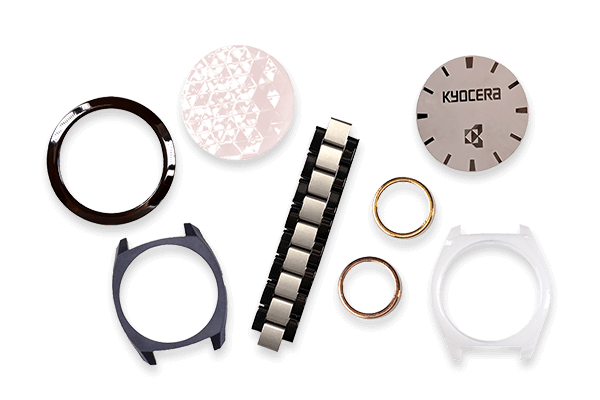

Kyocera is active worldwide in a wide range of sectors. Kyocera uses highly sophisticated materials to produce extremely reliable products both for the major global industries as well as its end consumers.

Business to Business

Consumer

News

- Kyocera recognized as an environmental and innovation leader03 April 2024

- Corporate

- Kyocera launches new inkjet printhead "KJ4B-EX1200-RC" with ink recirculation29 February 2024

- Printing Devices

- ESK-SIC GmbH and KYOCERA Fineceramics Europe GmbH cooperate for the sustainable production of silicon carbide06 February 2024

- Fine Ceramic Components

- VELUX sees Kyocera ceramic technology as important contributor to vacuum glass technology11 January 2024

- Fine Ceramic Components

EVENTS

-

ambiente

January 26-30, 2024

Frankfurt am Main, Germany

https://ambiente.messefrankfurt.com/frankfurt/en/planning-preparation/visitors.html

Hall 9.0, Booth # C21 -

The Advanced Ceramics Show

May 15-16, 2024

Birmingham, UK

https://advancedceramicsshow.com/

Booth # 1807 -

BIEMH

June 03-07, 2024

Bilbao, Spain

https://biemh.bilbaoexhibitioncentre.com/en/

Hall 3, Booth # F-21 -

SMTconnect

June 11-13, 2024

Nürnberg, Deutschland

https://smt.mesago.com/nuremberg/en.html

Hall 4, Booth # 4-204 -

The Battery Show Europe

June 18-20, 2024

Stuttgart, Germany

https://www.thebatteryshow.eu/en/Home.html

Hall 8, Booth # A66 -

AMB

September 10-14, 2024

Stuttgart, Germany

https://www.messe-stuttgart.de/amb/en/

Hall 3, Booth # 3B40

About

The Kyocera Group

With an altruistic philosophy and a unique management system, the Kyocera Group emphasizes corporate citizenship through trust among stakeholders, sustainable growth, and a favorable impact on our environment and society. We invite you to learn more about our history, management tradition and corporate social responsibility (CSR) via the links below.