MEGACOAT Cermet PV7005 for machining cast iron

09 April 2009

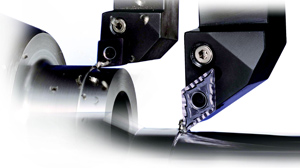

Kyoto/Neuss – The Japanese technology corporation, Kyocera, a pioneer in the development of fine ceramic products, is introducing a new CERMET indexable insert for the final machining of cast iron. A new, patented MEGACOAT layer significantly improves resistance to wearing.

The substrate for Kyocera's PV7005 indexable insert is a special TiC-TiN (titanium carbide/ titanium nitride) Cermet for machining cast iron. The new Cermet and the MEGACOAT-layering together result in wear resistance that is some 50 percent higher than that of conventional materials. In addition, the patented MEGACOAT-PVD layering also prevents notch wear and allows steady and precise machining.

With an oxidation temperature that is about 200°C higher than conventional models, the PV7005 guarantees above average notch wear resistance. Outstanding heat resistance also ensures steady machining at high temperatures.

In 1975, Kyocera began producing cutting tools. Today, the company provides finished products and components to nearly all sectors of the processing industry. The products are tailor-made to meet individual needs. They are also used in general engineering and by carmakers and their suppliers.