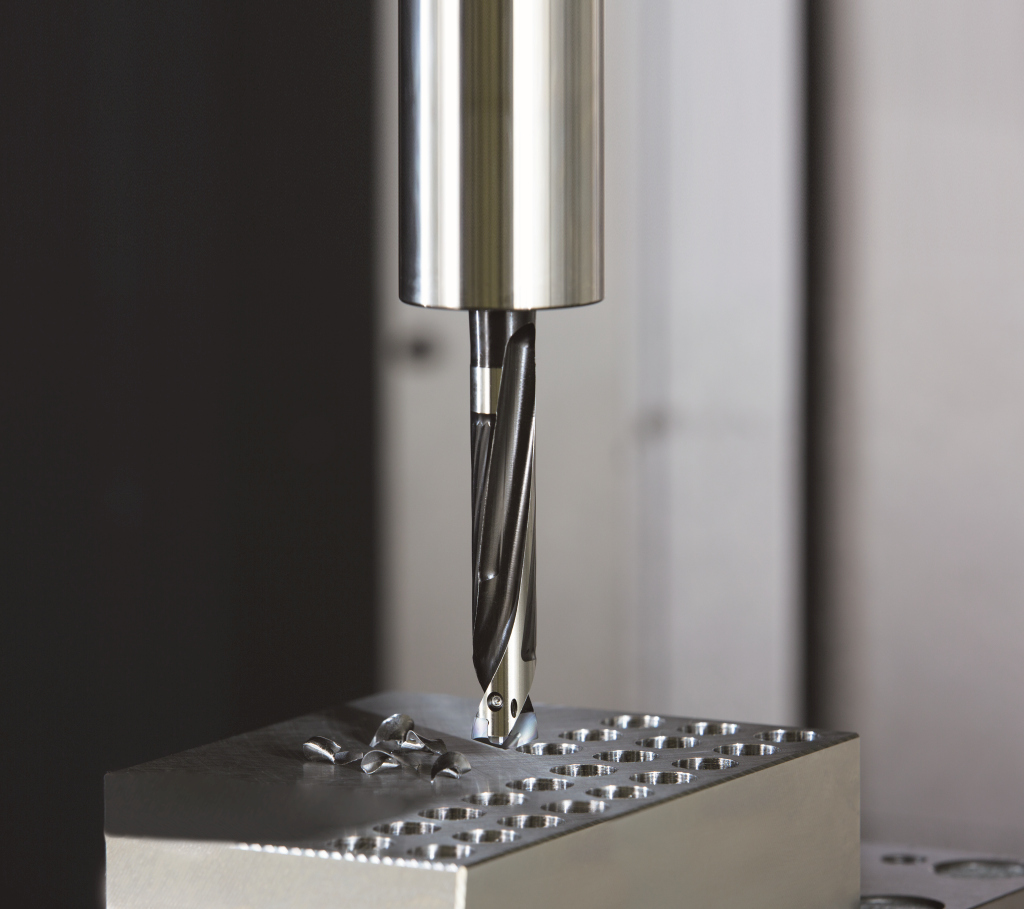

KYOCERA presents innovative Magic Drill DRA: Modular drill with low cutting force for excellent drilling accuracy

Reduced deflection thanks to optimised drill bit, high smoothness during deep drilling, good chip control and easy drill bit replacement yield highly efficient and extremely precise results.

20 April 2016

Kyoto/Neuss – The advanced ceramics specialist Kyocera is launching the new Magic Drill DRA, a highly efficient drill with an easily replaceable drill bit, which achieves superb drilling accuracy at a low cutting force. The optimisation of the drill bit and chip flute as well as a special coating ensure high stability and long tool life.

Magic Drill DRA’s development background

Presently, there are a diverse range of materials to be processed which are also becoming lighter and lighter. Therefore, a drill needs to be capable of being used for different materials while maintaining high drilling precision.

Drilling accuracy is a function of the holder’s stability and the degree of deflection during drilling. A larger drill bit reduces deflection and thus increases stability and drilling accuracy. However, clamping or jamming of chips may occur due to the smaller chip flute, particularly when drilling deep holes. With its Magic Drill DRA, Kyocera optimally resolves this conflict between greater stability and smaller chip flute.

The Magic Drill DRA is a highly efficient modular drill that combines superb drilling accuracy with excellent chip control. The drill bit ensures high stability. It is 20% larger than that of competitors, and its helix angle and flute design have been optimised — which prevents deflection. The excellent drilling accuracy is achieved by reducing the cutting force by means of a special S-shaped chisel edge that minimises thrust and vibration during drilling.

Consistent chip removal is made possible thanks to an optimised chip section and support groove with a wider fillet (5D, 8D). When signs of wear and tear appear, it is easy to replace the drill bit in no time at all. The screw that holds the drill bit to the holder merely has to be loosened, not completely unscrewed, and then tightened again after the replacement. Moreover, Kyocera’s MEGACOAT NANO PR1535 coating ensures long service life of the drill bit and stable processing of different materials.

For more information about Kyocera: www.kyocera.eu

Press Material

- Press Release (pdf) (70.19 KB)

- Press Picture (jpg) (313.61 KB)

- Press Picture (jpg) (601.99 KB)

- Press Picture (jpg) (411.44 KB)

- Press Picture (jpg) (223.04 KB)