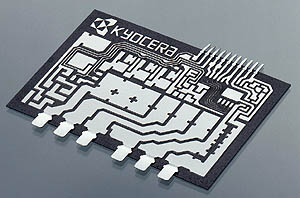

KYOCERA Copper Bonded Silicon Nitride Substrate Achieved 5000 Cycles of Temperature

30 May 2005

KYOCERA announced its Copper Bonded Silicon Nitride Ceramic Substrate achieved 5,000 cycles of air to air temperature cycling test with a condition of –60 to +175 degrees centigrade without any failure.

Its base ceramic substrate is Kyocera Silicon Nitride (Si3N4) with 850 MPa of flexural strength and 5.0 MPam1/2 of fracture toughness. This Silicon Nitride is much stronger compared to other ceramics, for example, Alumina (Al2O3) with 274 MPa of flexural strength and 3.3 MPam1/2 of fracture toughness and Aluminum Nitride (AlN) with 400 MPa and 2.7 MPam1/2. Copper is bonded on the Silicon Nitride substrate by an active metal bonding (AMB) method using Silver-Copper-Titanium brazing metallization. Active Metal Bonding is a

stronger method of adhering copper to ceramics when compared to conventional copper bonding methods without metallization, typically using a copper oxide process. The AMB copper bonded Silicon Nitride substrate is much stronger, mechanically than conventional copper bonded Alumina and Aluminum Nitride substrates. Kyocera AMB Silicon Nitride technology is suitable as a substrate material for use in power microelectronics applications in automotive, aerospace and other harsh environment.

stronger method of adhering copper to ceramics when compared to conventional copper bonding methods without metallization, typically using a copper oxide process. The AMB copper bonded Silicon Nitride substrate is much stronger, mechanically than conventional copper bonded Alumina and Aluminum Nitride substrates. Kyocera AMB Silicon Nitride technology is suitable as a substrate material for use in power microelectronics applications in automotive, aerospace and other harsh environment.