KYOCERA Enters the Inkjet Printhead Business

World’s Fastest Drop-on-Demand Inkjet Printhead Opens

16 April 2008

Kyocera Corporation (President: Makoto Kawamura) is pleased to announce that it has developed a high-speed inkjet printhead, the main component of inkjet printers, for commercial applications. The new KJ4 Series printhead has been successfully produced and sold on a limited basis; Kyocera will launch global development of its inkjet printhead business in April 2008.

The highly reliable KJ4 Series printhead has attained a speed of 200 meters per minute for full-color, high-speed printing, making it the world’s fastest*1 at high definition with a resolution of 600 dpi x 480 dpi. When the resolution is increased to 600 dpi x 600 dpi, the speed is 150 meters per minute. The product offers a wide print line, spanning 4.25 inches (108 millimeters), making it the widest in the world*2. The launch of full-scale business development comes after approximately one year of tests using the actual equipment.

This product uses basic technology that Kyocera began jointly developing with Brother Industries, Ltd., in 2002. Kyocera independently conducted further development and succeeded in bringing the product to commercialization.

“We expect that inkjet printheads developed by Kyocera will finally make it possible for inkjet printers to enter the mainstream commercial printing market,” stated Hitoshi Takao, General Manager of Kyocera’s Thin Film Components Group. “The superior performance and reliability of Kyocera’s KJ4 Series printheads will provide opportunities for inkjet printers to develop into new markets in the future.”

*1 Measured by Kyocera (as of March 25, 2008)

*2 On a stand-alone module basis (as of March 25, 2008)

Business name | Inkjet Printhead Business |

Commencement of Sales | April 1, 2008 |

Sales Target | 1 billion yen for the first fiscal year, 10 billion yen for the next fiscal year |

Location of Plant | Hayato Plant in Kagoshima, Japan |

■ Features of Kyocera’s KJ4 Series Inkjet Printhead

Kyocera’s specially developed piezo actuator*3

During product development, Kyocera applied its own sophisticated piezoelectric ceramics technology to successfully develop a compact piezo actuator. The actuator is a critical element in attaining high-speed, high-definition and high-reliability printing.

In addition, Kyocera utilized its extensive range of printhead technologies gained through the commercialization of thermal and LED printheads. Leveraging its design and manufacturing technology, Kyocera arranged the actuator and compact nozzles that accompany it to fit in a dense, regular pattern in the industry’s widest printhead. Kyocera also ensured that the components work with a high level of precision.

By optimizing its broad knowledge and technology base as a global leader in fine ceramic products, Kyocera created a new device that enables high-speed, high-definition and high-reliability inkjet printing that was hitherto difficult to achieve.

*3 The piezo actuator (piezo element) is the most important component of the inkjet printhead in attaining high-speed, high-definition printing. The piezo actuator is a key device for inkjet printers, as it controls the discharge of ink by the piezoelectric effect.

1. The world’s fastest “drop-on-demand” inkjet printhead has achieved a print speed of 150 meters per minute*

* This is the case with the MJP600, manufactured by Miyakoshi Printing Machinery Co., Ltd., which uses Kyocera standard ink and combines two heads in the scanning direction (two heads are used, each with a speed of 75 meters/minute). The MJP600 can print the equivalent of approximately 1,000 sheets of A4 paper per minute.

2. High-definition 600 dpi printing attained

The KJ4 Series printhead’s 2,656 ink nozzles are arranged in a 4.25-inch width. Even with the high speed of printing, this configuration enables high-definition printing with 600 dpi resolution.

3. Simplified design

Kyocera’s broad inkjet printhead, with a width of 4.25 inches, allows designs with fewer heads, thus simplifying configuration.

4. Various types of printing are supported

The KJ4 Series printhead supports both waterborne pigment ink and UV ink, making it possible to print not only on paper but also on various materials, ranging from cloth to non-absorbent materials, such as plastic films.

5. High reliability

Kyocera’s KJ4 Series printhead was installed in the MJP600 printer, made by a major commercial printer manufacturer, Miyakoshi Printing Machinery Co., Ltd. (Head office: Narashino City, Chiba Prefecture, President: Iwao Miyakoshi) and has been in use since April 2007. The printer provided on-demand printing at client sites for approximately one year. Kyocera obtained favorable results for both quality and reliability through this equipment test, verifying the superior reliability of its product.

You can see the high-speed inkjet printer equipped with Kyocera’s KJ4 Series printhead in the booth of Miyakoshi Printing Machinery Co., Ltd., at Drupa 2008, an exhibition of print industry equipment. Drupa 2008 takes place from May 29 through June 11, 2008, at the Dusseldorf Trade Fair Center in Germany; the event is held once every four years.

■ Product specs

Printing Method | Piezoelectric DOD Line Inkjet Printhead |

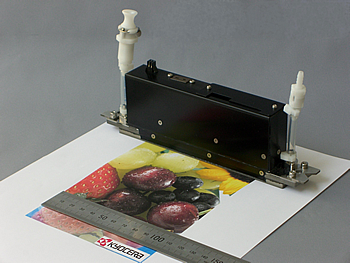

Size | 200×25×58 (mm) (width × depth × height) |

Number of nozzles | 2,656 nozzles/head |

Print width | 4.25 inches (108 mm) |

Resolution | 600 dpi x 600 dpi |

Printing speed* | 75 meters/minute (when resolution is 600 dpi x 600 dpi ) |

Droplet size* | From 4 pL to 21 pL |