KYOCERA Introduces “Magic Drill DRV” for High-Speed, High-Efficiency Hole Drilling at Reduced Cost

The Japanese advanced ceramics specialist KYOCERA will introduce a variety of new cutting tool solutions at this year´s EMO trade fair in Hannover, Germany.

18 August 2017

Kyoto/London – Among the new innovations, new grades for super heat-resistant alloys, PR005S and PR015S for turning are now available. A newly developed substrate improves toughness of the inserts and prevents notch-wear, realizing stable machining. Kyocera’s original PVD coating technology “MEGACOAT Hard” was adopted for these grades, featuring high hardness and excellent heat resistance.

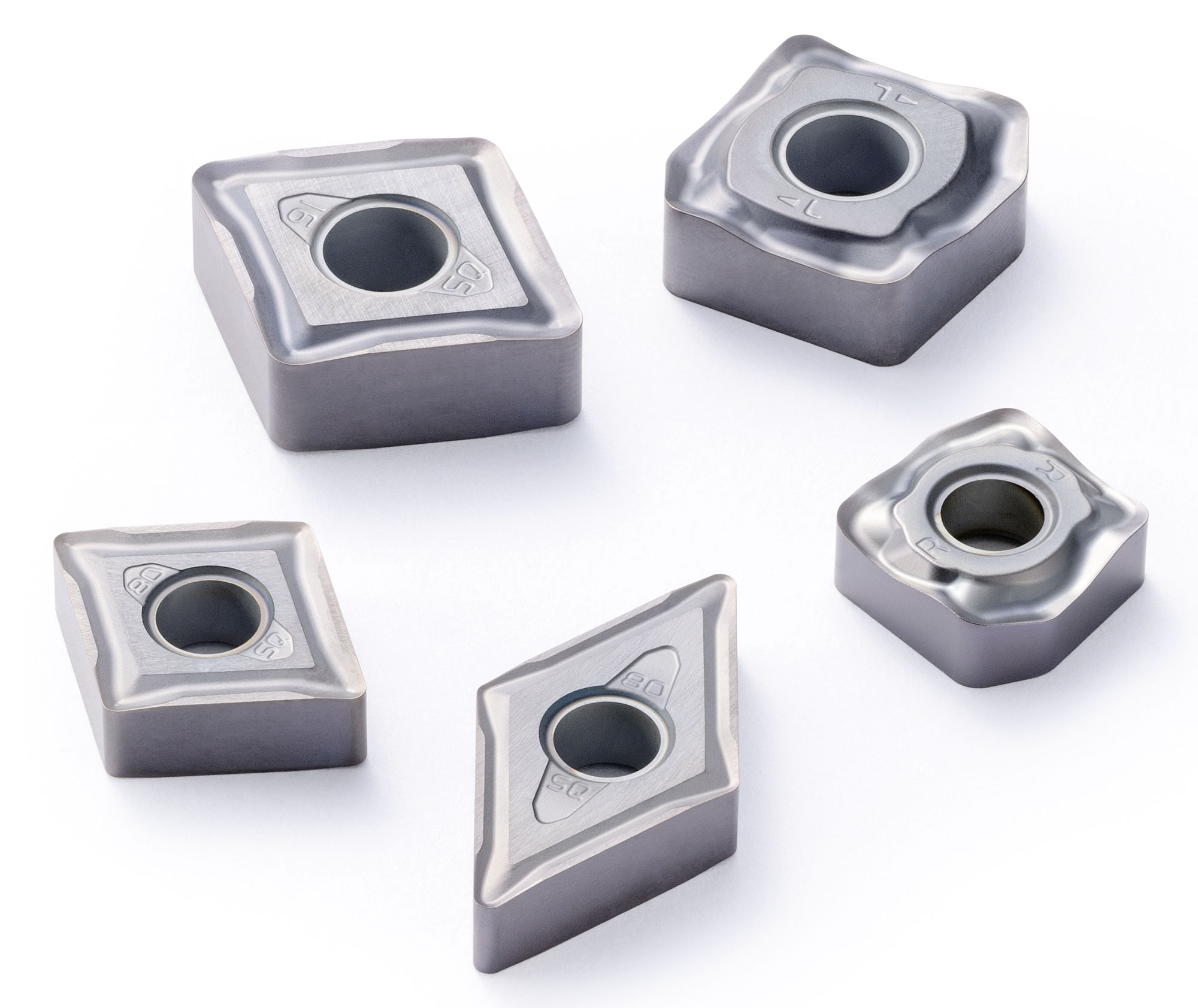

New chipbreakers for super heat-resistant alloys – SQ and SX chipbreakers for turning

These new chipbreakers are specially designed for roughing applications and semi-finishing of super heat-resistant alloy. Conventional tools lead to short or unstable tool life which results in low productivity and frequent set-up time. High thrust force by popular geometries (R, S types) for roughing generate vibration and have limited application range. Thus it is difficult to secure machining rigidity for turbine parts, for example. The semi-finishing SQ chipbreaker and rough machining SX chipbreaker can solve such problems. The SX chipbreaker has a special nose shape (handed type). A unique axial face design reduces cutting edge temperature which leads to tool life improvement. A negative lead angle of 60° prevents burrs and secures enough cutting depth. The SX chipbreaker reduces radial force which prevents chattering and improves productivity. Therefore, the SX chipbreaker maintains high performance even in high-speed machining. The SQ chipbreaker improves tool life and productivity in semi-finishing operation. A special axial face design decreases cutting edge temperature. The angled cutting edge is effective in reducing burrs and notching.

Other innovative products include the new MFAH milling cutter for aluminium machining with a hybrid body design and PCD inserts. It performs with less burring, low resistance and high efficiency. Furthermore, a range of 3D-printed cutting tool and toolholder solutions will be presented including chip-free PCD reamers for cylinder head water connection holes and vibration damping toolholders. Also on display is the latest multi-flute PCD reamer for valve body spool bore machining. With up to 8 cutting edges this innovation allows for exceptionally fast reaming of high-quality bores in cast aluminum parts.

New MagicDrill DRV (indexable drill) and MagicDrill DRA (drill bit)

The newly developed line of indexable modular drills, Magic Drill DRV, to be used mainly for hole drilling in the machine tool business, will also be presented. It is ideally suited for the automotive, aerospace and medical device industries, since it combines a chemical vapor deposition (CVD) coated insert on the outer edge and a physical vapor deposition (PVD) coated insert on the inner edge. The MagicDrill DRA is a highly efficient drill with an easily replaceable drill bit, which achieves superb drilling accuracy at a low cutting force. In addition to the lineup of 3D, 5D and 8D, a 1.5D version is now available.

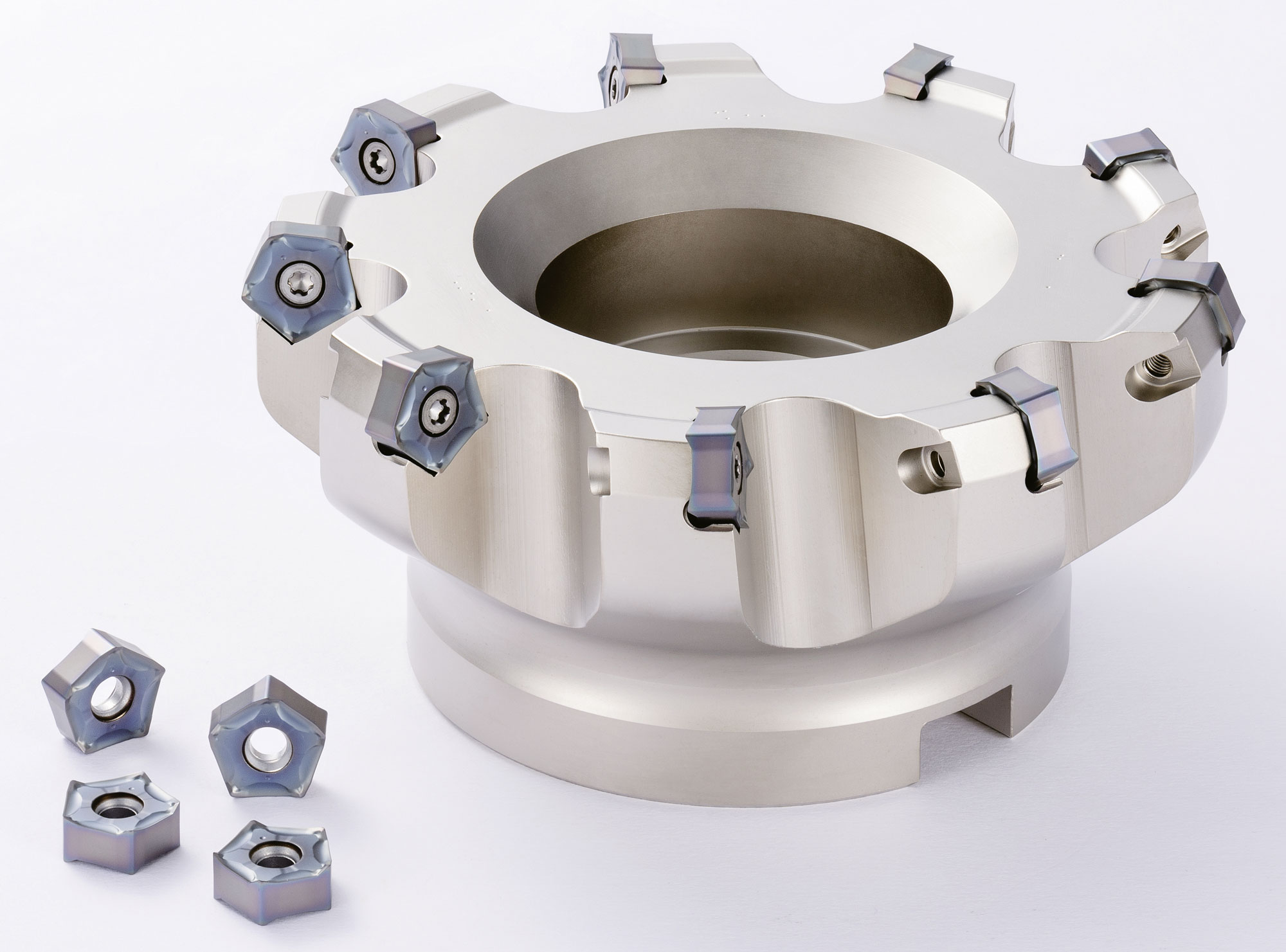

New face mill cutter – MFPN66

The MFPN66 is a highly efficient face mill cutter with an approach angle of 66°. The double-sided pentagonal inserts offer 10 cutting edges per insert. It is specially developed for smaller cutting depths and diameters. The main force and feeding force is equal to 45° type cutters but radial force is 40% lower.

High-tech grade for milling application – CERMET TN620M

This is designed for milling applications and achieves excellent fracture resistance with a surface-hardened layer using gradient composition technology. With super micro-grain cermet, TN620M allows stable machining and long tool life with excellent surface finish. The grade is available for the MFPN45, MFPN66, and MFWN face milling cutter series.

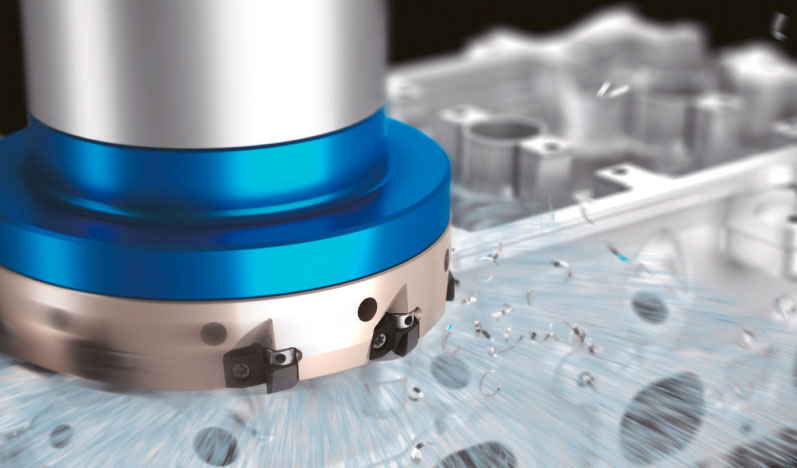

Full line-up of MFH high feed cutter series

Kyocera's successful high feed cutter series combines several geometries, grades and toolholders with line-up ranges from 8 mm to 160 mm, which enable a variety of applications. The low cutting force design ensures high efficiency and stable high feed machining in a wide range of cutting parameters. A line-up expansion is now being offered such as for the new MFH Micro screw-on type starting from diameters of 8 mm to 16 mm, MFH Mini shell mill types from 40 mm to 50 mm with up to 8 teeth.

KYOCERA SGS Precision Tools, Inc.

Kyocera will show a wide range of round tools with an updated line-up from recently acquired Kyocera SGS Precision Tools especially for aerospace and difficult to cut material applications.

For more information on Kyocera: www.kyocera.eu

Press Material

- Press Release (pdf) (367.63 KB)

- Press Picture (jpg) (274.04 KB)

- Press Picture (jpg) (49.29 KB)

- Press Picture (jpg) (224.29 KB)

Contact for journalists

Daniela Faust

Manager Corporate Communications

E-mail: daniela.faust@kyocera.de

Latest News

- Kyocera Receives Japan’s Environment Minister’s Award for Record 9th Consecutive Year

- Kyocera to Participate in Self-Driving Bus Test Project on JR East BR Lines

- Innovative, durable, and beautiful: Kyocera presents high-quality kitchen tools demonstrating the advantages of its ceramic technology at the BBC Good Food Show in Birmingham from November 29 – December 2, 2018.

- Inamori Foundation Awards the 34th Kyoto Prize to Scientists and Artist in the Fields of "Advanced Technology", "Basic Science", and "Arts and Philosophy"

- KYOCERA reflects on integral philosophy of Founder Dr. Kazuo Inamori to respect the divine and love people

- Kyocera wins CEATEC Award for “Amcenna” IoT Antenna

- KYOCERA celebrates 27 years of sustainability at the core of operations

- Kyocera wins Supplier Award

- Kyocera presents a firework display of innovations at the electronica 2018

- KYOCERA introduces reliable, Waterproof Branch Connector for harsh conditions of automotive electronics

- KYOCERA to Build New Manufacturing Plant in Kanagawa, Japan for Conductive and Insulation Pastes

- KYOCERA steps up expansion strategy with Czech acquisition

- KYOCERA Group to Exhibit Innovative Technologies and Products at CEATEC JAPAN 2018 Tradeshow Oct. 16-19

- KYOCERA introduces a new 12.1” WXGA LCD Module for Off Highway Applications

- KYOCERA at AMB 2018: a world premiere and a number of new products